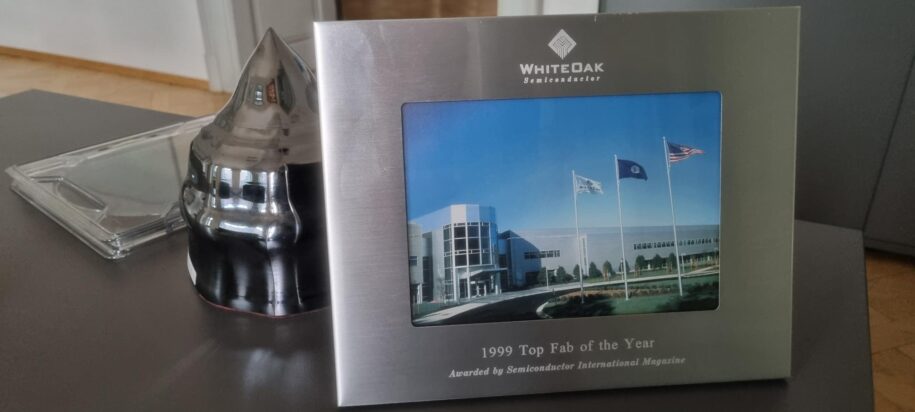

In 1999, the White Oak Semiconductor Fab in Richmond, VA, was awarded the prestigious “Top Fab of the Year” (yes, that actually existed – proof attached!) by the leading semiconductor magazine of the time. Back then, I was a young engineer on the ramp up team and I recall that the reason we were chosen for the award was the incredibly short time in which we were able to ramp up production. Naturally, we share the credit for the award with others on the team – the people that had planned the ramp up, set up the infrastructure and provided the tools – but our role was getting all the software systems in place before the first silicon even arrived at wafer test.

That experience taught me the following: that the accessibility of all data for cross-correlation and deep dives into potential culprits of yield loss is a decisive factor in the success of a yield ramp – whether for a new product, a new process line or a completely new fab.

The bigger the financials at stake, the more important it is to get your product to market fast. For a new factory that foots a multi-billion-dollar bill, every day that you can pull the start of production up earlier saves you several hundreds of thousands of dollars of interest in tied capital. Therefore, installing a yield management system ahead of the critical yield ramp up phase may very well pay for itself.

At DR YIELD, we’ve had many success stories of YieldWatchDog customers that we supported early on in their production ramp. Additionally, engaging early in the process opens up the possibility of adding features that address customer-specific requirements and training users ahead of time, thus taking the stress out of introducing new software during the hectic ramp-up phase. As I learned back in the late 90ies: preparation is key to a successful yield ramp.