After

attending the semiconductor manufacturing conference SEMICON Europa in Munich

last week, our main takeaway is clear: smart manufacturing has permeated every

aspect of the semiconductor industry as its principles are applied not only to each

process in the manufacturing cycle, but to each and every detail along the way,

ultimately increasing efficiencies and productivity while also making

semiconductor manufacturing more adaptable and sustainable.

Big data

analytics are used in smart manufacturing to streamline the manufacturing

processes, optimize the supply chain, analyze tools

and eliminate workplace inefficiencies.

Engineering

yield management systems make semiconductor manufacturing and test data easily

accessible. Manufacturers that use yield management tools spend less time

gathering data and have more time for analysis. A yield analysis system transforms

data into valuable, actionable information, making the data work for you.

DR YIELD’S YieldWatchDog

is the premium yield analysis solution that does both of these things: it makes

big data easily accessible and also performs complex and advanced analysis. YWD

monitors the entire manufacturing process, providing equipment monitoring and

full supply chain visibility. Enhanced data visualization tools enable

manufacturers deep insight into their manufacturing and test data.

In

addition, YieldWatchDog provides a deep root cause analysis of the data,

allowing manufacturers to take immediate action when there’s an issue. Its predictive

analytics can prevent yield excursions by sending warnings to engineers when an

anomaly is detected.

YieldWatchDogXI is an artificial intelligence layer with smart

pattern recognition, tool analytics and multivariate data monitoring,

harnessing the power of the data and unlocking its value through cutting-edge

AI analytics.

State-of-the-art

new smart fabs are designed and built using detailed digital 3D models to

determine the most efficient placement of tools, conveying systems, water lines

and pumps to name a few.

Digitalization

enables different platforms of an organization worldwide to communicate and

work together, sharing data and knowledge. Using smart goggles, for example,

technicians and engineers can collaborate on projects, troubleshoot or share

new technologies – clearly a huge advantage over travelling.

Another

interesting way smart manufacturing is practiced is by using so-called

scheduling software that calculates the most efficient path and timing for each

lot and tool, taking into account restrictions and requirements, thus increasing

throughput, decreasing the downtime on tools while ensuring wafers are produced

in a timely manner.

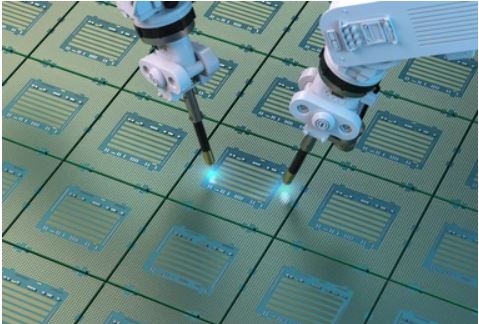

Robotics are

and always have always been essential to the advanced semiconductor

manufacturing industry. They cannot be beat in terms of precision, are capable

of learning and collecting large amounts of data and can be continuously

reprogrammed and reconfigured. Robotics perform the majority of manufacturing

tasks and transport the highly sensitive wafers.

The

semiconductor industry continues to push the limits of technology further than

anyone could have imagined. Smart manufacturing is the most technologically

advanced and efficient methodology to increased throughput, higher efficiency,

less waste, less downtime and more productive shifts, with more clearly defined

employee tasks and improved materials planning. By applying smart manufacturing,

semiconductor manufacturers can massively increase revenues while driving down

costs and also decreasing CO² output. We are proud to be able to

offer a turnkey solution as part of smart manufacturing.

About DR YIELD software & solutions GmbH

DR YIELD provides the leading-edge advanced analytics software YieldWatchDog for analysis and control of semiconductor manufacturing and test data. This enables semiconductor manufacturers as well as Fabless companies to improve important manufacturing dimensions such as equipment availability, throughput, operating costs and yield. Once installed YieldWatchDog allows you to get actionable insights into your data. For detailed information click here