Cutting-edge Yield Management Systems integrate Big Data, Smart Data, Machine Learning and AI analytics to enable semiconductor manufacturers to gain deep insight fast and save costs.

Semiconductor manufacturers are under constant pressure to increase yields and cut costs. Yield Management Systems (YMS) are designed specifically to meet the needs of semiconductor manufacturers, enabling them to investigate yield excursions, streamline the manufacturing processes, optimize the supply chain, analyze tools and eliminate workplace inefficiencies.

In terms of data challenges, semiconductor manufacturers must deal with the increasing complexity of chips, while more sophisticated testing equipment and sensors at every step of the process contribute heavily to the avalanche of data being collected.

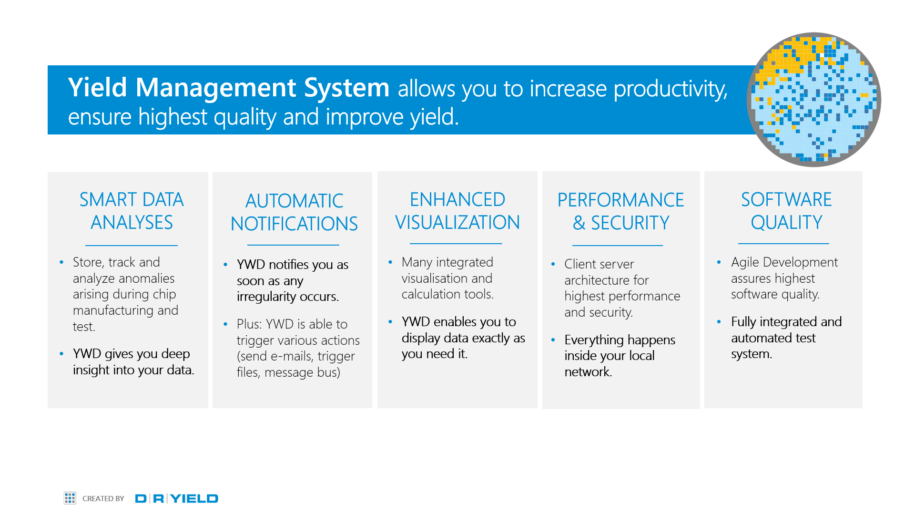

A YMS is used for facilitating data storage, data analysis and data management, while also providing actionable insights from the huge amounts of data. Manufacturers using YMS save on engineering time that normally goes to gathering and cleaning all the data by making the manufacturing and test data easily accessible.

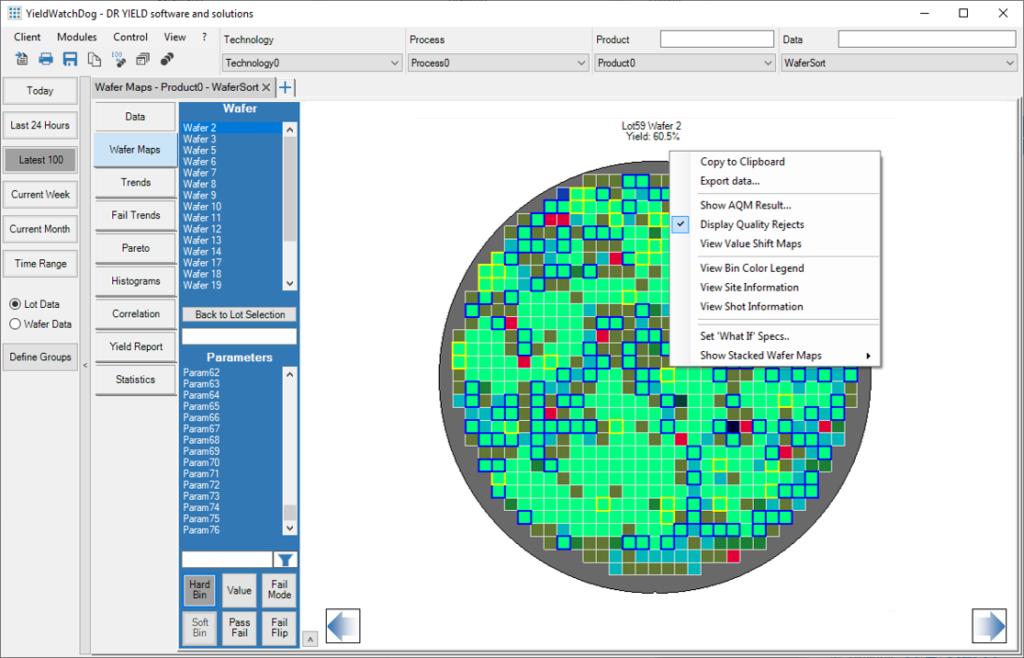

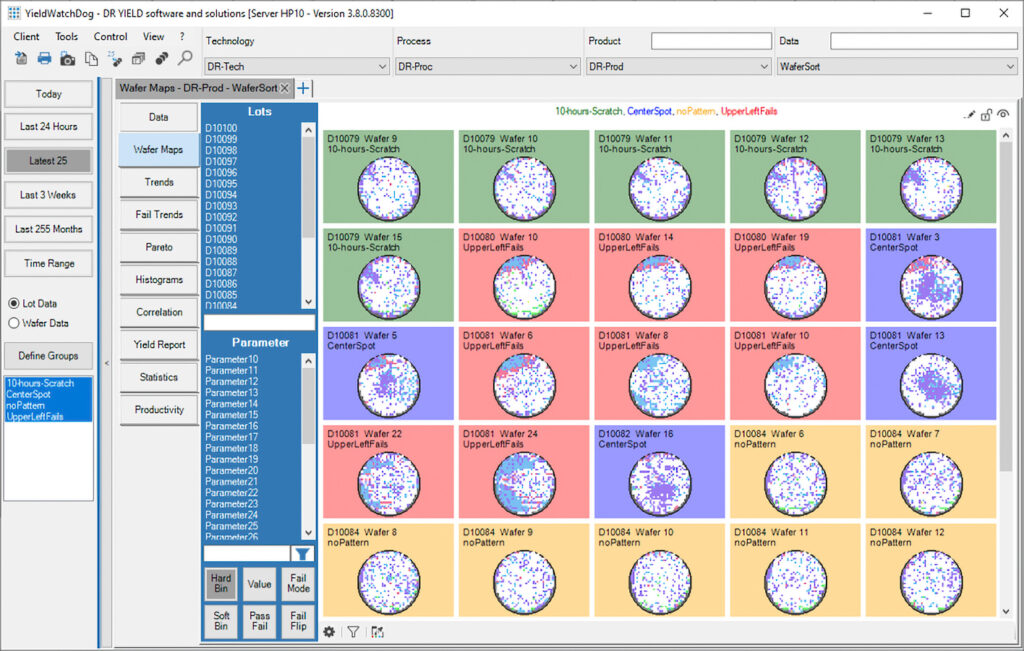

Enhanced data visualization tools give manufacturers deep insight into their manufacturing and test data to uncover patterns, as well as to calculate trends and correlations. Automatic anomaly detection can even prevent yield excursions by sending warnings to engineers as soon as an irregularity in the data is detected.

To achieve the highest yield, reduce defectivity of semiconductor devices and solve semiconductor manufacturing problems effectively, a YMS monitors the entire manufacturing process, providing equipment monitoring and tracing the origin and movement of material.

In the highly competitive, high volume, data-intensive semiconductor industry, with fabs manufacturing at or near capacity, YMS have become indispensable.

Yield management systems provide a comprehensive solution tailored to the semiconductor manufacturing environment. They compile the enormous amounts of data being collected at every step of the manufacturing and testing process and condense and transform the data into valuable, actionable information companies can use.

Cutting-edge AI applications, machine learning, predictive analytics and other AI algorithms enhance fundamental YMS functions to help manufacturers get the maximum benefit from their data with automatic pattern recognition, tool combination analytics and multivariate monitoring.

The key to increasing yield often lies in quickly identifying the factors or combination of factors that contribute to a specific problem or in quickly pinpointing which wafers or lots were affected by a particular issue. A YMS helps uncover these hidden correlations and patterns.

A YMS integrates multiple innovative and powerful tools to help semiconductor manufacturers and fabless customers quickly make smarter, data-driven decisions that save costs and improve products and services.